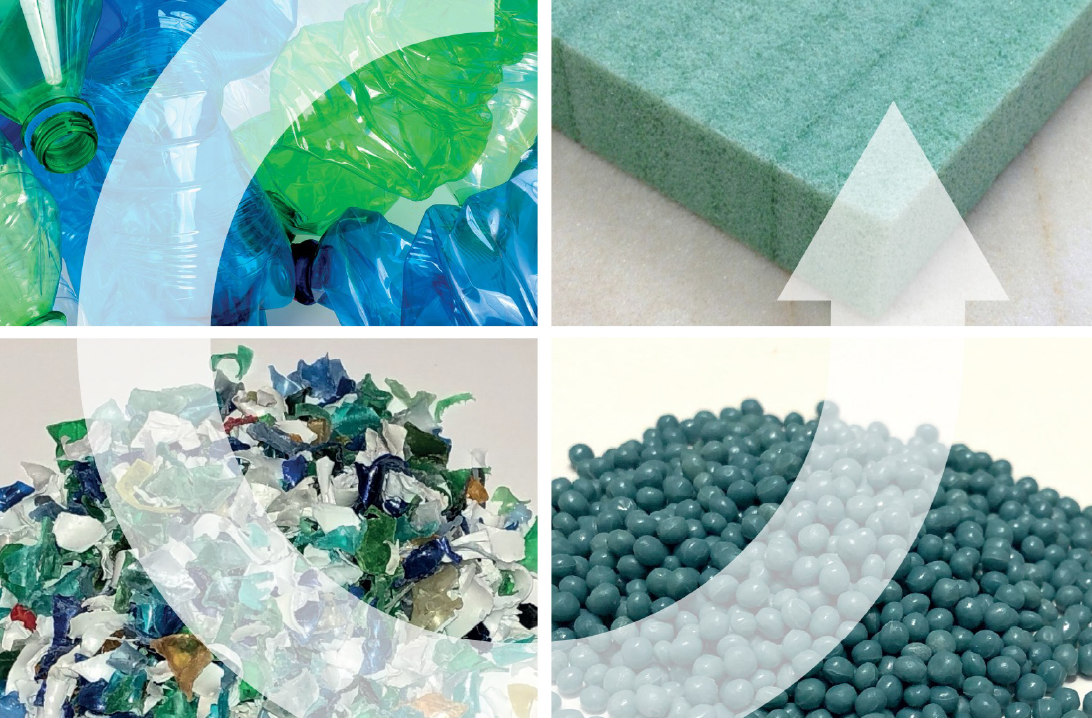

Gurit recycles several hundred million plastic bottles per year and convert them into structural PET foam used to build wind turbine blades - generating clean energy - and many more applications such as boats or buildings.

Many materials commonly used in boatbuilding today eventually end up polluting the environment due to ending up in landfills or are simply abandoned. Our natural fibre solutions ampliTex and powerRibs do not only offer environmental benefits and viable end-of-life options, but also novel design opportunities and excellent vibration damping.

Gurit’s new PRIME™ 37 high performance resin uses bio-containing raw materials as standard, by sourcing chemicals produced from renewable and sustainable feedstocks. The result is the excellence you’ve come to expect from Gurit PRIME™ products with market-leading health and safety standards, no compromise in performance and at no extra cost.

Ampro Bio Resin

Introducing the Ampro Bio by Gurit, which has the highest bio content on the market. The epoxy is perfect for the repair and refit of wooden structures and interiors due to its rapid cure at temperatures as low as +5°C and its flexibility of use in multiple applications.

The AMPRO™ range includes a bio-based alternative. The more environmentally friendly AMPRO™ BIO option does not compromise on performance, retaining all of the key properties you would expect from a state-of-the-art multi-purpose epoxy. It was developed using chemicals derived from plant-based materials that are by-products of the food chain rather than petro-chemicals. Thanks to the 40% bio-content, AMPRO™ BIO is a more sustainable product, which has a richer colour and further enhances the natural grain of the wood being coated. Alongside the sustainability benefits, the complete AMPRO™ range mirrors Gurit’s commitment to health and safety using base chemicals with low hazards to minimise the risk to users.

Bio as standard with Prime 37

PRIMETM 37 is suitable for the female moulding of large, complex components incorporating advanced fibres such as carbon and aramid*. Typical projects include spars, hulls and reinforcing structures. PRIMETM 37 offers outstanding performance in a variety of liquid infusion processes including SCRIMPTM, RIFT (resin infusion under flexible tooling), VARTM (vacuum assisted resin transfer moulding) and RTM (resin transfer moulding). PRIMETM 37 resin uses a wide range of hardeners to give a range of working times and cure speeds. This enables the gel time of the resin to be closely matched to the required infusion time for any particular size of moulded part. It achieves excellent mechanical and physical properties, including a high Tg from a moderate (50°) post cure.

Introducing the Ampro Bio by Gurit, which has the highest bio content on the market. The epoxy is perfect for the repair and refit of wooden structures and interiors due to its rapid cure at temperatures as low as +5°C and its flexibility of use in multiple applications.

The AMPRO™ range includes a bio-based alternative. The more environmentally friendly AMPRO™ BIO option does not compromise on performance, retaining all of the key properties you would expect from a state-of-the-art multi-purpose epoxy. It was developed using chemicals derived from plant-based materials that are by-products of the food chain rather than petro-chemicals. Thanks to the 40% bio-content, AMPRO™ BIO is a more sustainable product, which has a richer colour and further enhances the natural grain of the wood being coated. Alongside the sustainability benefits, the complete AMPRO™ range mirrors Gurit’s commitment to health and safety using base chemicals with low hazards to minimise the risk to users.

PRIMETM 37 is suitable for the female moulding of large, complex components incorporating advanced fibres such as carbon and aramid*. Typical projects include spars, hulls and reinforcing structures. PRIME 37 offers outstanding performance in a variety of liquid infusion processes including SCRIMPTM, RIFT (resin infusion under flexible tooling), VARTM (vacuum assisted resin transfer moulding) and RTM (resin transfer moulding).

PRIME 37 resin uses a wide range of hardeners to give a range of working times and cure speeds. This enables the gel time of the resin to be closely matched to the required infusion time for any particular size of moulded part. It achieves excellent mechanical and physical properties, including a high Tg from a moderate (50°) post cure.

Sustainable Reinforcements

Gurit® Kerdyn™ Green have been developed to respond to the growing need for structural core materials with stable properties and improved resin uptake performance. Additionally the Gurit® Kerdyn™ Green allows to comply with the wind energy aim to reduce foot print and reinforce overall goals of waste reduction.

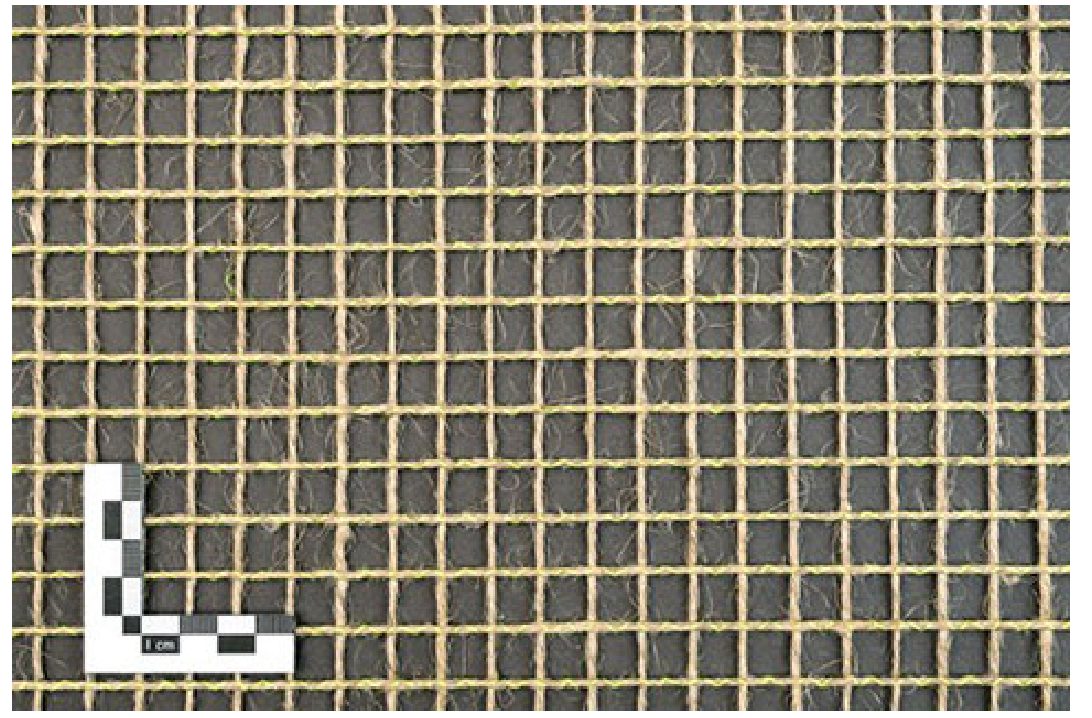

Bcomp ampliTex is a next-generation natural flax fibre novelty enabling innovative composite material solutions for various applications. It includes different technologies - non crimp, low twist, no twist, braids and ampliTex™ fusion. AmpliTex is designed to serve several different purposes. Hence, it involves different technologies and offers diverse range of the products in order to adapt to all customer needs.

The powerRibs™ technology is an extremely lightweight natural fibre reinforcement grid. Inspired by leaf veins, it provides maximum stiffness at minimum weight by creating a rib structure on one side of a thin-walled shell element.

Thanks to these reinforcements, the CO2 footprint of semi-structural parts, e.g. exterior panels, can be reduced by 75% vs carbon fibres while matching performance. For interior panels, weight can be reduced by up to 50% and plastic by up to 80% at matching performance.

The chemical industry is one of the biggest industries in the world. Our sector plays a key role in the fields of innovation and sustainability. Adhesives and sealants are used in many products and therefore have a major impact on the world. SABA takes its responsibility in this seriously and places sustainability high on its agenda. Together with you, we are on the way to ‘a sustainable bond’.

-

Specialists work on the sustainability of SABA products everyday

-

Lower environmental impact, both products and production

-

Free of hazard symbols